In order to attach the chain and cranks to the drive shaft of the grinder I had to machine a piece of metal that fit on to the drive shaft and threaded to a bicycle freewheel gear set. Using the Evergreen Machine Shop and the help of a fellow student and machining genius, Jimmy, I machined a piece of steel rod to fit on to the drive shaft and lock on with a key. This process involved using various tools, some of which I would like to highlight below.

Here is my ode to the dial calipers. This instrument is for measuring and it is more precise than I ever thought I would need. However, when machining parts, precision is like popeye's canned spinach.

This is a lathe. This machine really opened my eyes to the possibilities of machining. It also made me realize how extremely dangerous it is. Luckily, Jimmy was there to make sure I didn't mangle myself.

Here is a picture of the lathe taking a cut while I was machining the threads.

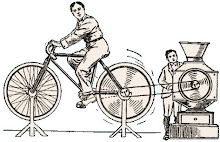

Here is what the grinder looks like with the gears mounted on the drive shaft.

In order to attach the chain and cranks to the drive shaft of the grinder I had to machine a piece of metal that fit on to the drive shaft and threaded to a bicycle freewheel gear set. Using the Evergreen Machine Shop and the help of a fellow student and machining genius, Jimmy, I machined a piece of steel rod to fit on to the drive shaft and lock on with a key. This process involved using various tools, some of which I would like to highlight below.

In order to attach the chain and cranks to the drive shaft of the grinder I had to machine a piece of metal that fit on to the drive shaft and threaded to a bicycle freewheel gear set. Using the Evergreen Machine Shop and the help of a fellow student and machining genius, Jimmy, I machined a piece of steel rod to fit on to the drive shaft and lock on with a key. This process involved using various tools, some of which I would like to highlight below. Here is my ode to the dial calipers. This instrument is for measuring and it is more precise than I ever thought I would need. However, when machining parts, precision is like popeye's canned spinach.

Here is my ode to the dial calipers. This instrument is for measuring and it is more precise than I ever thought I would need. However, when machining parts, precision is like popeye's canned spinach. This is a lathe. This machine really opened my eyes to the possibilities of machining. It also made me realize how extremely dangerous it is. Luckily, Jimmy was there to make sure I didn't mangle myself.

This is a lathe. This machine really opened my eyes to the possibilities of machining. It also made me realize how extremely dangerous it is. Luckily, Jimmy was there to make sure I didn't mangle myself. Here is a picture of the lathe taking a cut while I was machining the threads.

Here is a picture of the lathe taking a cut while I was machining the threads. Here is what the grinder looks like with the gears mounted on the drive shaft.

Here is what the grinder looks like with the gears mounted on the drive shaft.