I have had a particularly long hiatus posting images of the machine, but not to fret, I have been busy.

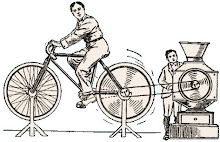

Using pedal powered innovative design to inspire and educate people about possibilities.

In order to attach the chain and cranks to the drive shaft of the grinder I had to machine a piece of metal that fit on to the drive shaft and threaded to a bicycle freewheel gear set. Using the Evergreen Machine Shop and the help of a fellow student and machining genius, Jimmy, I machined a piece of steel rod to fit on to the drive shaft and lock on with a key. This process involved using various tools, some of which I would like to highlight below.

In order to attach the chain and cranks to the drive shaft of the grinder I had to machine a piece of metal that fit on to the drive shaft and threaded to a bicycle freewheel gear set. Using the Evergreen Machine Shop and the help of a fellow student and machining genius, Jimmy, I machined a piece of steel rod to fit on to the drive shaft and lock on with a key. This process involved using various tools, some of which I would like to highlight below. Here is my ode to the dial calipers. This instrument is for measuring and it is more precise than I ever thought I would need. However, when machining parts, precision is like popeye's canned spinach.

Here is my ode to the dial calipers. This instrument is for measuring and it is more precise than I ever thought I would need. However, when machining parts, precision is like popeye's canned spinach. This is a lathe. This machine really opened my eyes to the possibilities of machining. It also made me realize how extremely dangerous it is. Luckily, Jimmy was there to make sure I didn't mangle myself.

This is a lathe. This machine really opened my eyes to the possibilities of machining. It also made me realize how extremely dangerous it is. Luckily, Jimmy was there to make sure I didn't mangle myself. Here is a picture of the lathe taking a cut while I was machining the threads.

Here is a picture of the lathe taking a cut while I was machining the threads. Here is what the grinder looks like with the gears mounted on the drive shaft.

Here is what the grinder looks like with the gears mounted on the drive shaft.

TA DAAAA Here she is, the Omega VI grinder from Compatible Technology International. Now that the grinder is here I can estimate the width of the machine and make all the final welds!!!

TA DAAAA Here she is, the Omega VI grinder from Compatible Technology International. Now that the grinder is here I can estimate the width of the machine and make all the final welds!!!

This is the TIG (Tungston Inert Gas) torch. It holds the Tungston steel that acts as the electrode.

This is the TIG (Tungston Inert Gas) torch. It holds the Tungston steel that acts as the electrode. Here is a mill that I used to mill a track for the seat mount.

Here is a mill that I used to mill a track for the seat mount. Here is a picture of me welding on the seat mount to the frame. (above and below)

Here is a picture of me welding on the seat mount to the frame. (above and below)

Here is a picture of a pipe clamp. This little fella has been worth it's weight in gold. I've been cutting all of the tubes with a hack saw and coping them with files while holding the tubes with this clamp. Everybody constantly tells me that I could do it faster using a grinding wheel, but I enjoy the precision and the work out of doing it with my arms. Believe that.

Here is a picture of a pipe clamp. This little fella has been worth it's weight in gold. I've been cutting all of the tubes with a hack saw and coping them with files while holding the tubes with this clamp. Everybody constantly tells me that I could do it faster using a grinding wheel, but I enjoy the precision and the work out of doing it with my arms. Believe that. This is a picture of the sand blaster. Those circular holes in the machine are where your hands stick in. It always reminds me of the beginning of the Simpsons where Homer is holding the plutonium.

This is a picture of the sand blaster. Those circular holes in the machine are where your hands stick in. It always reminds me of the beginning of the Simpsons where Homer is holding the plutonium.

Here are pics of the central frame that I have welded so far. You can see the bottom bracket shell (where the cranks attach) on the lower right side of the picture directly above.

Here are pics of the central frame that I have welded so far. You can see the bottom bracket shell (where the cranks attach) on the lower right side of the picture directly above. Above you can see the central frame mounted on the two bike frames that are being used for the majority of structural support. Below is a side view of the same thing.

Above you can see the central frame mounted on the two bike frames that are being used for the majority of structural support. Below is a side view of the same thing. Below is a picture of the jig an I used to build the frame. This jig was constructed by a Metal Shop Aide, Thomas, who got his plans off of instructables.com. Thomas is also pictured below and I would like to put a special thank you out to Thomas, your help will be rewarded 10 fold in hazelnut butter!

Below is a picture of the jig an I used to build the frame. This jig was constructed by a Metal Shop Aide, Thomas, who got his plans off of instructables.com. Thomas is also pictured below and I would like to put a special thank you out to Thomas, your help will be rewarded 10 fold in hazelnut butter!